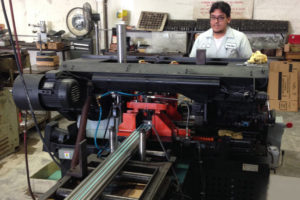

Specializing in processing both tubing and bar stock, at Green’s Metal Cut-off we offer accurate and precise band saw cutting services. With more than 35 years of band sawing experience, we cut an extensive range of materials in any volume, from small orders to long production runs. Producing exceptional cut quality, our machines feature high-speed operation and generate a uniform cutting action, which allows us to ship parts accurately and promptly.

Size & Tolerance Capabilities

Using automatic, heavy-duty band saws, we can handle any type of material 1″ to 11″ in diameter and efficiently cut lengths measuring from 0.2″ to 47.0″. Standard tolerances are +/- .015 for lengths up to 6″ and +/- .030 for lengths over 6″ and up to 47″, but we can obtain closer tolerances upon request. Our technically skilled production staff matches the blade construction, tooth configuration, band speed, and other operational parameters to the physical material, its shape, and dimension to keep operations as efficient and cost-effective as possible.

Material Capabilities

We cut round, square, hex, and rectangular bar and tubing constructed from a wide variety of metals. Along with aluminum, copper, beryllium, and all types of steel and steel alloys, we process metals such as tungsten, zinc, and hard to cut alloys like aircraft alloys. We use an arsenal of measuring tools to ensure close length and perpendicular tolerances on every production order

Whether requirements call for low or high volumes, we turn jobs quickly and accommodate tight deadlines. We serve customers in a multitude of industries, including aerospace, defense, medical, automotive, marine, lighting, and many, many others.

For more information about our band saw cutting services or to request a quote, contact us directly.