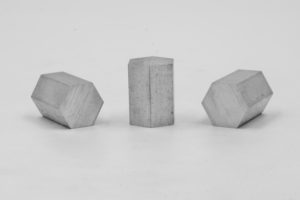

Our cold saw cutting capabilities apply to an extensive selection of machinable metals and we frequently use this cutting method when manufacturing screw machine products and turned parts. We handle round, square, hex, and rectangular profiles and process them in any volume, from small orders to long production runs.

Advantages of Cold Saw Cutting

Using a cold saw avoids heating the material to be cut, and the process produces burr-free cut edges, which eliminates the need for secondary operations. Our technicians consider many aspects, such as the material, its size, and its thickness as well as the angle and shape of the cut to choose the correct blade and feed rate. We have the capacity to make cuts quickly to achieve a high rate of production while upholding tolerances as close as ± 0.005″.

Material Capabilities

Our cutting equipment enables us to generate clean cuts in alloy steel, carbon steel, and stainless as well as aluminum, copper, zinc, and many other metals, including superalloy grades with levels of hardness that can be challenging to cut. We handle raw material with diameters measuring up to 4-3/4″ and produce accurately cut lengths anywhere in the 0.250″ to 75.0″ range. Using a combination of visual inspection methods and instruments such as gages and comparators, we ensure that all products we ship comply 100 % with specifications.

Serving customers in a broad range of industries, including aerospace, defense, appliance medical, automotive, marine, lighting, consumer goods, and many others, we are very responsive and turn jobs around quickly and accurately.

For more information about our cold saw cutting capabilities or to request a quote, contact us directly.